Water-based UV coatings can be considered aesthetically equivalent to bicomponent acrylic and polyurethane solvent-based coatings. The range is composed of both pigmented and transparent products. In the latter case, the main feature is the ability to achieve almost any color without limits on the shades, with excellent coverage and light stability, thereby overcoming the typical limits of polyester or acrylic UV coatings. Thanks to their physical drying, water-based UV coatings also allow to coat three-dimensional objects. Last but not least, it is possible to carry out mixed coating cycles when necessary, using acrylic UV base coats and water-based UV top coats, which make the most of the advantages of the two types of technology.

Polyester and polyacrylic UV coatings

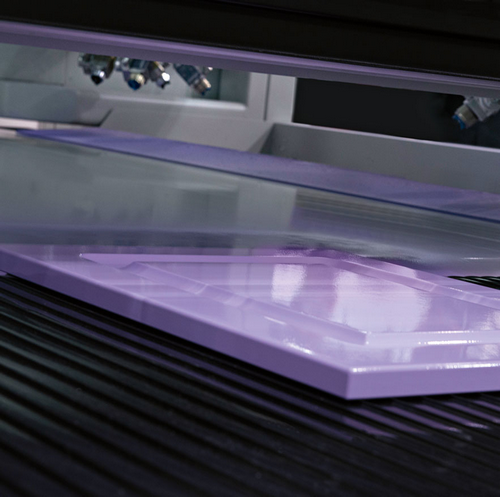

Widely used in the coating of flat panels, thanks in part to their relatively low cost, polyester and polyacrylic UV coatings deliver sufficient reactivity for the requested in-line speed and offer a good level of finish. They are formulated with unsaturated polyester resins dissolved in styrene, which functions as a solvent and has the capacity to react with the resin, thus determining the total solid content of the coating. Polyacrylic coatings combine the characteristics of polyester coatings and acrylic coatings, offering excellent performance/cost ratios.

Acrylic UV coatings

Compared to polyester UV coatings, acrylic UV coatings have a lower level of environmental impact, since the monomers they contain have a far lower level of volatility with respect to the styrene contained in polyester UV coatings, allowing to obtain products with 100% solid content. They offer excellent elasticity, adhesion and chemical/physical resistance. In addition, through the use of appropriate primers, they make it possible to resolve the problems that typically affect resinous woods and issues relating to adhesion on difficult surfaces such as melamine paper, plastic and glass. Thanks to their high reactivity, the products specifically formulated for the coating of profiles and frames satisfy the requirement for processing at high transport speed, which is a very common requirement in this sector.

Reg Office: Room 435, Building 9, No.2568 Gudai Road, Minhang District, Shanghai, China.

Pilot Lab: Building 1, No. 589 Qinling Street, Shijiazhuang High-tech Zone,Hebei, China.

Plant Unit 1: Xincheng town clean chemical park, Xinji, Hebei, China.

Plant Unit 2: Dongming County South Chemical Park, Heze City, China.

Tel: +86-21-34943721

Email:Massive@massivechem.com

Info@massivechem.com

Shanghai Massive Chemical Technology Co., Ltd. All Rights Reserved(C)2023 Supported by Record number:滬ICP備18008139號